Dairy Industry Clean-In-Place Technologies Evaluated In New White Paper

Mar 06, 2014

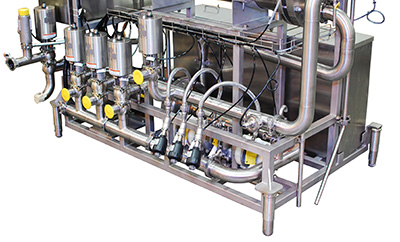

MILWAUKEE, WI — Federal Mfg., powered by ProMach, has researched and written a white paper on dairy industry clean-in-place (CIP) technologies – what to look for and what to avoid. The facts of CIP sanitation detailed in the white paper will help dairies ascertain whether they are utilizing best sanitation practices for their filling machines and are in compliance with Food Safety Modernization Act (FSMA) guidelines.

“With the detailed facts of CIP technology, dairies will be able to make the required calculations concerning time, temperature, flow, velocity, and solution concentration to determine whether the clean in place technology they are relying on for sanitation is actually sanitizing,” said Mike Collins, Vice President of Sales and Marketing at Federal Mfg. “This detailed information will help dairies conform to industry best sanitation practices and the intent of FSMA.”

White paper excerpts:

Thorough cleaning and sanitizing of equipment for processing and packaging dairy products is absolutely necessary for providing the highest level of food safety, product quality, and establishing and maintaining consumer trust. Proper sanitation also has a profound effect on lowering waste and improving output, both of which contribute to a healthy bottom line.

A flow rate of between 5 and 10 feet per second (1.5 to 3.0 meters per second) should generate a Reynolds number greater than 4,000 in a straight length of stainless steel sanitary tubing. When flows are measured within the 5 and 10 feet per second range, the flow is generally considered turbulent and thus provides good cleaning, scouring action.

The clean valve was removed from the filler bowl and dipped into water. Water was seen beaded up on the tube’s inside diameter, which meant there was un-removed milk fats and oils. One cannot argue with physics. The Reynolds number when calculated was well below 4,000 and the scouring action insufficient.

For more information about Federal’s sanitary, rugged, and long-lived filling and capping solutions including CIP, call 414-384-3200 and visit www.FederalMfg.com.

About Federal

Federal designs, manufactures, and supports complete rotary and inline net weight filling systems for free-flowing liquids. We serve a variety of markets including food and beverage applications such as edible oils, sauces, nutritional drinks, and protein supplements, as well as other high-value retail applications including automotive lubricants and additives, household cleaners and disinfectants, personal care products, agricultural chemicals, paints, and more. Federal’s net weight filling technology is ideal for applications needing exact dosing, with non-contact filling accuracy of ± 0.1% to minimize the giveaway of valuable products. For more than 70 years, Federal fillers have been recognized worldwide for dependable performance in demanding production environments as well as for an overall low total cost of ownership.

Media Contact

David Starck | [email protected]← Back to Press Releases